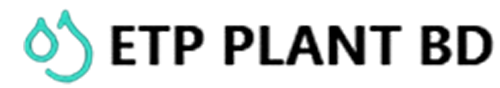

Best WWTP Supplier Bangladesh – Solutions for a Cleaner Future

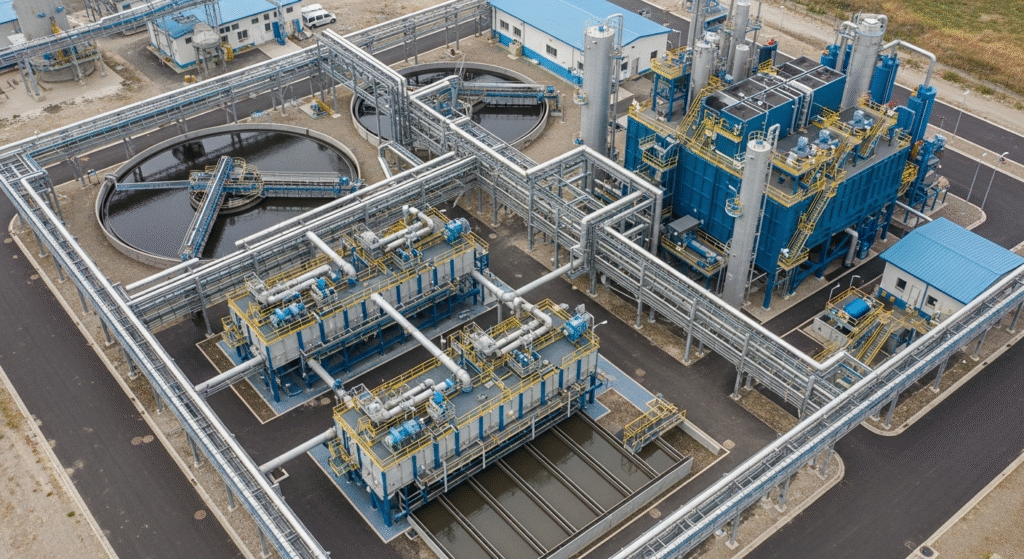

In an era of rapid industrialization and urban growth, wastewater management has become a vital issue in Bangladesh. To combat rising environmental pollution and water contamination, investing in high-quality wastewater treatment plants (WWTP) is no longer optional—it’s a necessity. If you’re searching for the Best WWTP Supplier Bangladesh, one name stands out for delivering reliable, […]

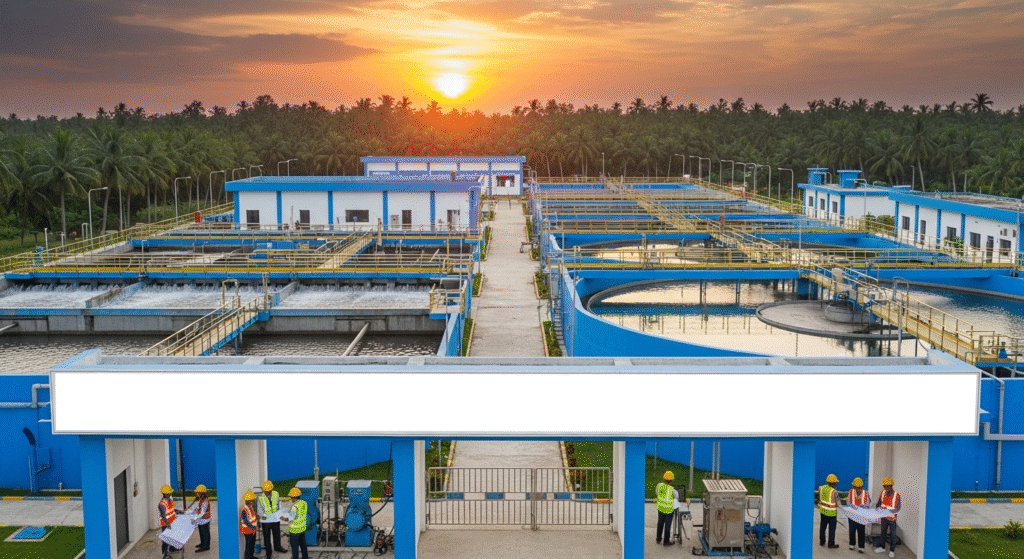

ETP plant supplier in Bangladesh

In Bangladesh’s rapidly growing industrial sector, proper wastewater treatment is becoming increasingly important. With stricter environmental regulations and growing awareness of sustainability, industries are now required to treat their effluent before discharging it into the environment. This has led to a rising demand for reliable and efficient Effluent Treatment Plants (ETPs). For businesses seeking a […]

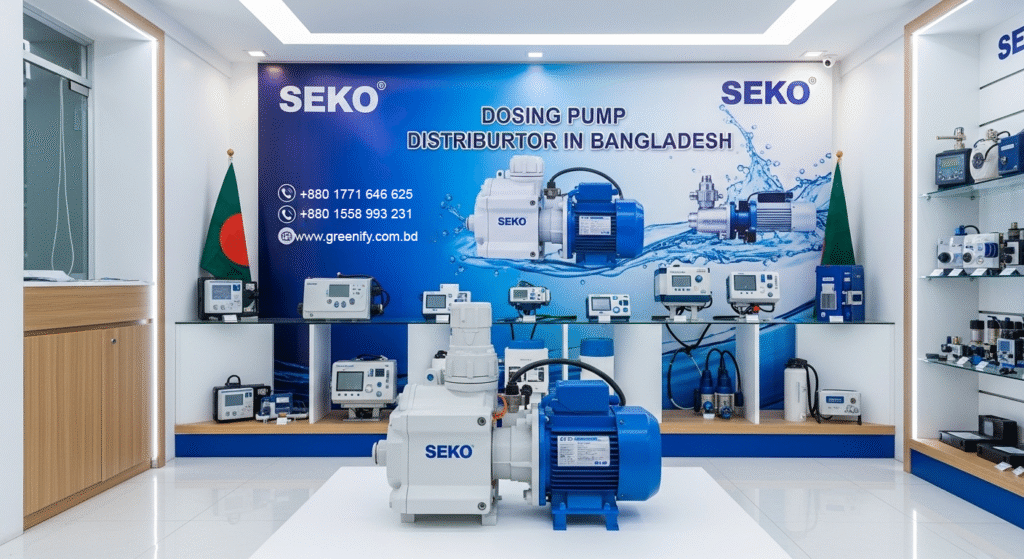

SEKO Dosing Pump Distributor in Bangladesh – Trusted Partner for Chemical Dosing Solutions

In the world of industrial automation and water treatment, precision and reliability are crucial. One of the most important tools in this field is the chemical dosing pump. Among the leading global brands in dosing technology, SEKO stands out for its innovation, efficiency, and wide range of solutions. In Bangladesh, the demand for reliable chemical […]

Top 5 ETP Plant Suppliers in Bangladesh

In Bangladesh, the importance of proper wastewater management has never been more critical. With industrialisation rapidly progressing and environmental concerns escalating, effluent treatment plants (ETPs) have become an essential part of sustainable operations for industries. ETPs ensure that water discharged from factories meets environmental standards before being released into nature, protecting both human health and […]

How to Choose the Right Industrial Effluent Treatment Plant for Your Business

In today’s world, industrial effluent treatment is essential for businesses across various sectors. Whether you are in the textile, pharmaceutical, food processing, or chemical industry, choosing the right Industrial Effluent Treatment Plant (ETP) is crucial to ensure waste management, regulatory compliance, and sustainable operations. In this blog post, we will guide you through the process […]